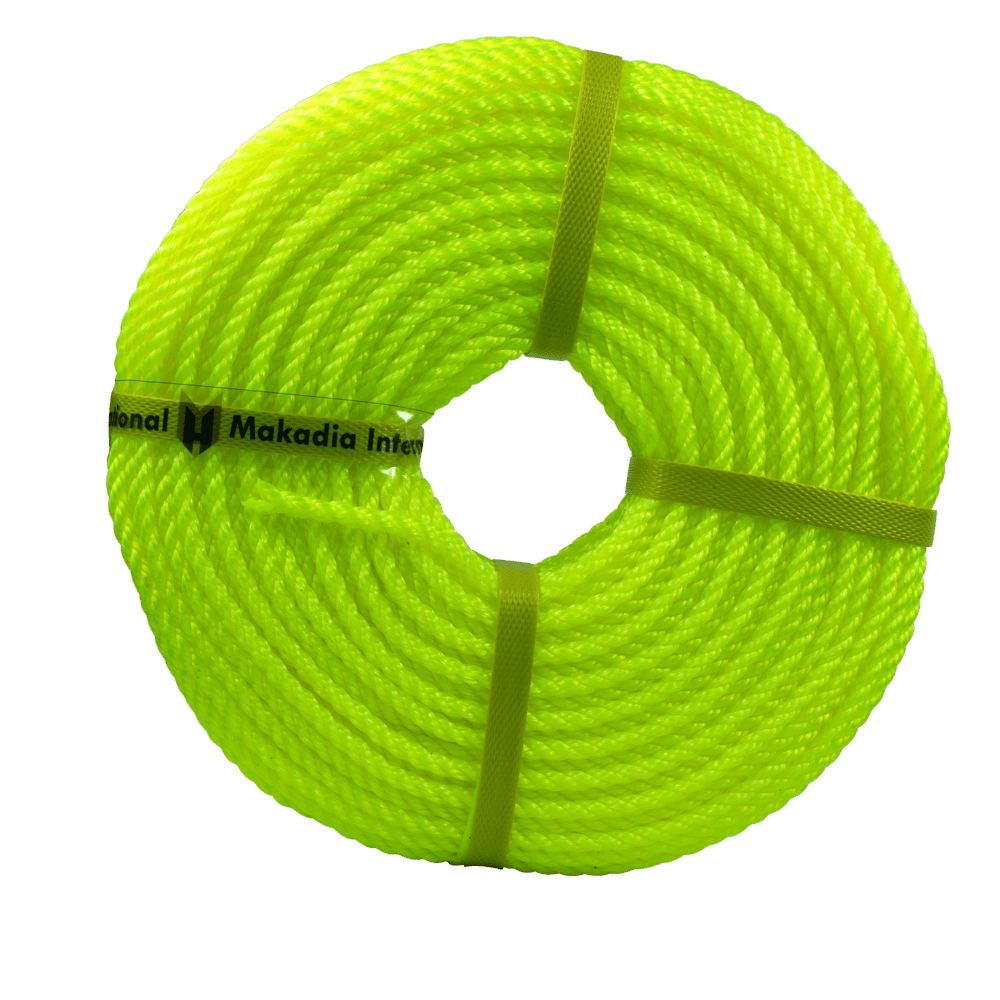

At Makadia International, we manufacture and export high-quality polyethylene monofilament ropes that are known for their excellent flexibility, durability, and resistance to harsh environmental conditions. These ropes are produced using single-strand extruded polyethylene fibers, resulting in a smooth-surfaced, lightweight rope that is easy to handle and highly functional across diverse applications.

Polyethylene monofilament rope offers exceptional resistance to UV rays, moisture, and most chemicals, making it ideal for prolonged outdoor use. Its ability to float on water and retain strength under extreme conditions makes it a preferred choice in the marine, aquaculture, agriculture, and transport sectors. The rope remains unaffected by saltwater, ensuring long-term performance in coastal and fishing environments.

We offer this rope in various diameters, colors, and spool sizes to meet specific client needs. From securing fishing nets to agricultural bundling and cargo handling, our polyethylene monofilament ropes are designed to deliver reliability with minimal maintenance. With a strong focus on quality, Makadia International ensures that every coil of rope meets international standards and provides unmatched value across industries.

Additional sizes and colors available to special order and also bulk order. we are ready to customize packing.

Features Of HDPE Rope

- Rope Range : 2 mm - 60 mm

- Color : Yellow, Blue, Red, Green, Orange, White, Black and Brown

- Range of rope : 3 & 4 Strand

- Available In : S & Z Twister Rope

- Tolerance :: Up to 9mm +/– 10%, 10mm to 14mm +/– 8%, 15mm & above +/– 5%

- Coil length :These ropes are available in 110/220/500 meters or in yards 100/200. (Long lengths are available on request.)

- Packing Details : PE ropes are generally packed individually in plastic bags and then coils are packed in woven bags for shipping.

Major usage

- Fishing

- Shipping

- Industrial Use

- Domestic Purpose

- Construction

- Seafaring

- For Truck Use and other

| Size | 1 MTR (gm) | 110 MTR (kg) | 220 MTR (kg) |

|---|---|---|---|

| 4 MM | 8.1 | 0.891 | 1.782 |

| 6 MM | 18.2 | 2.002 | 4.004 |

| 8 MM | 32.7 | 3.597 | 7.194 |

| 10 MM | 40.9 | 4.500 | 9 |

| 12 MM | 72 | 7.920 | 15.840 |

| 14 MM | 95 | 10.450 | 20.900 |

| 16 MM | 128 | 14.080 | 28.160 |

| 18 MM | 161 | 17.710 | 35.420 |

| 20 MM | 200 | 22 | 44 |

| 22 MM | 243 | 26.730 | 53.460 |

| 24 MM | 295 | 32.450 | 64.900 |

| 28 MM | 393 | 43.230 | 86.460 |

| 32 MM | 525 | 57.750 | 115.500 |